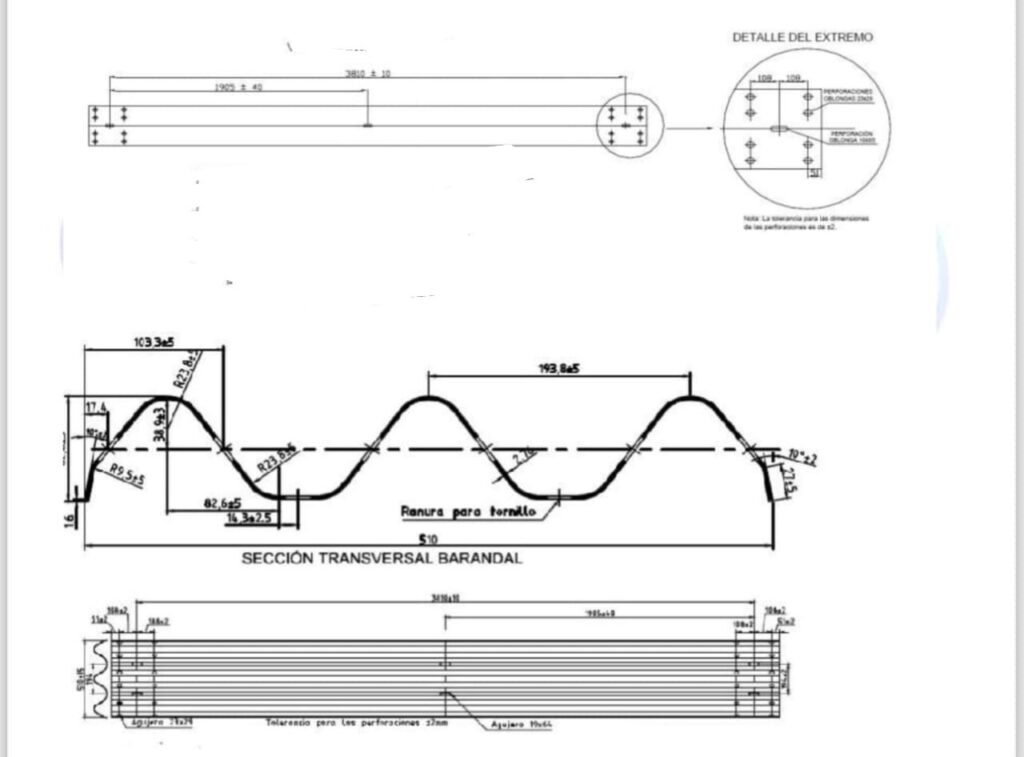

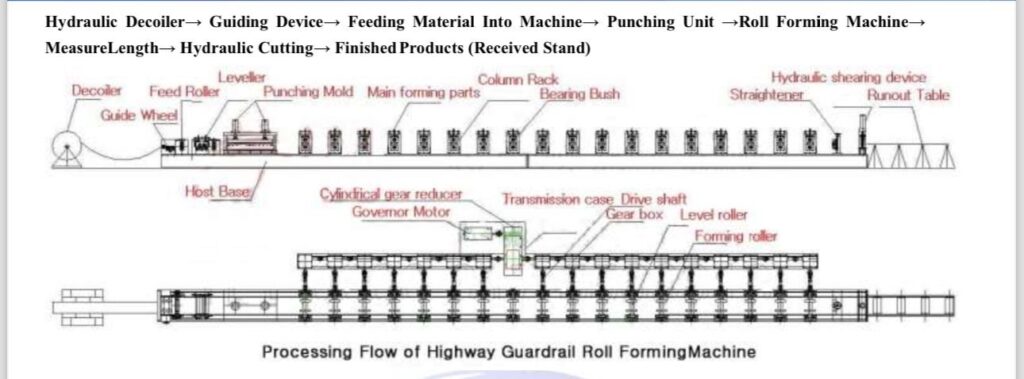

THRIE BEAM / W BEAM profile Making Machine

Technical Specification

| Technical specification | |

|---|---|

| Type of material to be process | CR/HR/GP |

| No. of station | 18 station |

| Steel Boday Stretcher | 450/765 MM I BEEM |

| Heavy Stend Material | 50x50x550 (mm) |

| Bearing | FAG |

| Housing | 60x160x250 (mm) |

| Forming speed | 8-10 meter/min |

| Roller material | EN –31 WITH HARDNING |

| Motor | ABB OR EQUALANT |

| Main motor with Gearbox | 40 HP (1 pic.) |

| Gearbox | 4 HP ( 16 Pic.) |

| Voltage | 440V-50HZ-3 Phase |

| Cutting system | Post, Hydraulic, Automatic |

| Length of machine | 40 - 50 feet approx |

| Weight of machine | 25-28 Ton approx. |

| Maximum Material thickness | 2 mm to 3 mm |

| Maximum width of coil | 800 mm |

| Accuracy level | Length ±3mm Bend or twist ±5 mm/meter dimension ±3 mm |

Equipment

1 De-coiler – Hydraulic

2 Entry gauge – Screw type manual

3 Leveller – 4 roller Lower & 3 Pressure roll

4 Capsule Punching press – Hydraulic

5 Main Roll forming machine – 18 station

6 Cutting press – post cutting, Hydraulic

7 Control panel – Delta

8 Hydraulic power pack – ABB motor, Yukon make valve

9 Run out table – Heavy

10 power pack – 2 pis.(1 decoiler,1 roll forming)

| De-coiler (Hydraulic) | |

|---|---|

| Type | Hydraulic (10 ton) |

| capacity | 10000 KG |

| Coil Id | 510 mm |

| maximum coil width | 800 mm |

| Main body | heavy fabricated |

| Drum expansion length | 470-530 mm |

| Motor | 5 HP |

| Power pack | 5 HP |

Main Roll Forming Machine

Fabricated machine bed

Stand Bracket type

Entry guides movement manual.

Roll tooling material EN-8 with Harding, cnc turning and hardcore plated.

Drive mechanism by chain drive.

| Motor | ABB or equal ant |

|---|---|

| Main motor with Gearbox | 40 HP |

| Material thickness minimum | 2.0 mm |

| Material thickness maximum | 3.0 mm |

| Maximum width of coil | 800 mm |

| Shaft diameter | 100 mm |

| Power pack | 20 hp |

Cutting Press

Type – Hydraulic

cutting – Post cutting

sensor – proxy type

cutting die material with hardening – WPS

Hydraulic Power Pack

Tank fabricated capacity – 400 letter.

Motor – 20 HP, 3 phase,1440 RPM ,Flange ,ABB

Direction control valve – NG-06-24V-DC (Yukon)

Pump – 1P series 27 LPM Duty

Section filter – SC3-30 (Hydro line)

Return line filter – T1-F2-08-B25 (Hydro line)

Level gauge – LG-03 (Hydro line)

Control Panel

Drive – VFD

HMI – Delta 7″

HMI 10” X 10” Touch Color screen – 01

Encoder – delta

contactor, SMPS, Relay

Auto single piece system

Auto machine length counting

Fabricated sheet metal enclosure

Easy mounting of components

PLC control mechanism system for high accuracy in length control

Front panel with operator interface, push button panel, operating indicators

protections shell be arranged by us near main panel console.