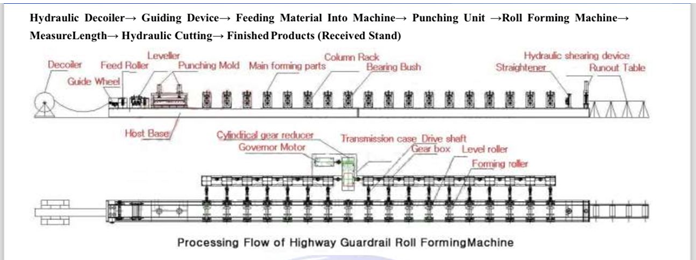

Thrie Beam W Beam

| Technical Specification | |

|---|---|

| Type of material to be process | CR/HR/GP |

| No. of station | 18 station |

| Steel Boday Stretcher | 450/765 MM I BEEM |

| Heavy Stend Material | 50x50x550 (mm) |

| Bearing | FAG |

| Housing | 60x160x250 (mm) |

| Forming speed | 8-10 meter/min |

| Roller material | EN –31 WITH HARDNING |

| Motor | 40 HP (1 pic.) |

| Main motor with Gearbox | 40 HP (1 pic.) |

| Gearbox | 4 HP ( 16 Pic.) |

| Voltage | 440V-50HZ-3 Phase |

| Cutting system | Post, Hydraulic, Automatic |

| Length of machine | 40 - 50 feet approx |

| Weight of machine | 25-28 Ton approx. |

| Maximum Material thickness | 2 mm to 3 mm |

| Maximum width of coil | 800 mm |

| Accuracy level | Length ±3mm Bend or twist ±5 mm/meter dimension ±3 mm |

| Equipment | |

|---|---|

| De-coiler | Hydraulic |

| Entry gauge | Screw type manual |

| Leveller | 4 roller Lower & 3 Pressure roll |

| Capsule Punching press | Hydraulic |

| Main Roll forming machine | 18 station |

| Cutting press | post cutting, Hydraulic |

| Control panel | Delta |

| Hydraulic power pack | ABB motor, Yukon make valve |

| Run out table | Heavy |

| power pack | 2 pis.(1 decoiler,1 roll forming) |

| De-Coiler (Hydraulic) | |

|---|---|

| Type | Hydraulic (10 ton) |

| capacity | 10000 KG |

| Coil Id | 510 mm |

| maximum coil width | 800 mm |

| Main body | heavy fabricated |

| Drum expansion length | 470-530 mm |

| Motor | 5 HP |

| Power pack | 5 hp |

| Main Roll Forming Machine | |

|---|---|

| Fabricated machine bed | |

| Stand Bracket type | |

| Entry guides movement manual. | |

| Roll tooling material EN-8 with Harding, cnc turning and hardcore plated. | |

| Drive mechanism by chain drive. | |

| Motor | ABB or equal ant |

| Main motor with Gearbox | 40 HP |

| Material thickness minimum | 2.0 mm |

| Material thickness maximum | 3.0 mm |

| Maximum width of coil | 800 mm |

| Shaft diameter | 100 mm |

| Power pack | 20 hp |

| Cutting Press | |

|---|---|

| Type | Hydraulic |

| cutting | Post cutting |

| sensor | proxy type |

| cutting die material with hardening | WPS |

| Hydraulic Power Pack | |

|---|---|

| Tank fabricated capacity | 400 letter |

| Motor | 20 HP, 3 phase,1440 RPM ,Flange ,ABB |

| Direction control valve | NG-06-24V-DC (Yukon) |

| Pump | 1P series 27 LPM Duty |

| Section filter | SC3-30 (Hydro line) |

| Return line filter | T1-F2-08-B25 (Hydro line) |

| Level gauge | LG-03 (Hydro line) |

| Control Panel | |

|---|---|

| Drive | VFD |

| HMI | Delta 7" |

| HMI 10” X 10” Touch Color screen | 01 |

| Encoder | delta |

| contactor, SMPS, Relay | |

| Auto single piece system | |

| Auto machine length counting | |

| Fabricated sheet metal enclosure | |

| Easy mounting of components | |

| PLC control mechanism system for high accuracy in length control | |

| Front panel with operator interface, push button panel, operating indicators | |

| protections shell be arranged by us near main panel console. |