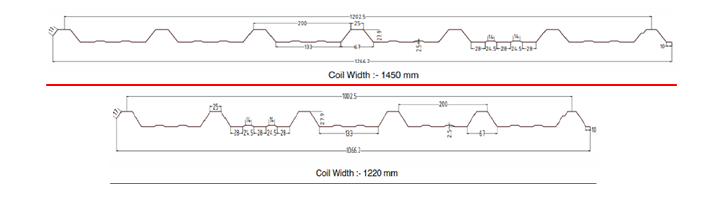

Roofing 1220 mm 6 Rib(6 Nali) 18 Station

| Technical Information | |

|---|---|

| Type of material to be Processed | PPGL / PPGI / NCGI |

| No. of Station | 18 |

| Max Width of Coil | 1220 mm |

| Min. Width of Coil | 500 mm |

| Max thickness of coil | 0.6 mm |

| Min. thickness of Coil | 0.3 mm |

| Variable Line Speed | 0 TO 18 mtr. / min |

| Automation level in performance | P.L.C CONTROLLED LENGTH |

| Accuracy Level | Length : +/- 2 M.M. BEND /TWIST : 1.5 MM/MTR DIMN : +/- 2 M.M. |

Equipment List

ROLL FORMING MACHINE

De Coiler 5 MT capacity – (Hydraulic)

Roll Forming Machine – (18 stand ).

Roll Tooling –

Hydraulic profile cutting press.

Hydraulic Power Pack.

Run out Table.

PLC type control panel.

Detail Line Specification

| 1) De Coiler ( 5 MT Capacity ) |

|

|---|---|

| All steel body construction | |

| Mandrel rotation | Automatic |

| Mandrel expansion by | Automatic |

| Loop System | Automatic |

| Breaking | Simple Brake |

| Max Width of Coil Can be Loaded | 1220 mm |

| Min width | 500 mm |

| Mandrel face length | 1400 mm |

| Drum nominal dia | 500 |

| Drum expansion range | 470 to 550 mm |

| Max. weight of coil can be loaded | 5,000 kg |

| Roll Forming Machine | |

|---|---|

| Fabricated machined bed | |

| Plate type work station option | |

| All roll shaft mounted on Ball Bearing | |

| Roller shaft material EN-8 hardened and ground. | |

| Entry guides with vertical guide rolls & lateral movement manual screw type | |

| Intermediate side guides with vertical guide rolls & all lateral | |

| movement manual screw type. | |

| Roll tooling material suitable for PPGI coil | |

| Roll tooling manufacturing on C.N.C. machines | |

| Drive Mechanism will be chain drive. | |

| No. of workstation | 18 |

| Max width of coil | 1220 mm |

| Min. Width of coil | 500 mm |

| Max. Thickness of coil | 0.6 mm |

| Min. Thickness of coil | 0.3 mm |

| Center distance of lower shaft to base plate | 150 mm |

| Horizontal distance between two stations | 450 mm |

| Max. Vertical Cent. Dist. Between lower to upper shaft | 300 mm |

| Motor ABB MAKE / Gear Box | 10 HP |

3) Roll Tooling

Forming Rollers material suitable for PPGI material super polished for long life & production without marking on profile. Above Configuration Roller suitable for profile as per following.

4)Hyd. Profile cutting press:- Ingis type Cylinder Type Hydraulic Post Cutting Unit

Cutting when profile ready as per require length +/- 2 mm and very good line speed. Press is designed for without slug while cutting.

Fabricated heavy duty base frame .

High speed operation.

Linear guide brass bush very useful when machine running high speed and constantly.

- Press is adjustable in 2 axis for align with profile

- More strength through Rack and

| Hyd. Profile Cutting Press:- Ingis Type Cylinder Type Hydraulic Post Cutting Unit | |

|---|---|

| Working capacity | 20 Tons |

| Hydraulic Power Pack | 100 liters |

| Pump | 01 |

| Filter | 01 |

| Solenoid valve | 02 nos |

5) Hydraulic Power Pack

| Hydraulic Power Pack | |

|---|---|

| Tank Fabricated Capacity | 100-Lts |

| Motor | 5 HP 3face 1440 rpm F class flange ABB |

| Direction control valve | NG-06-24v DC (Yuken) |

| Pump | 1P series 27 LPM Dowty |

| Section filter | SC3 - 30 (Hydro line) |

| Return line filter | T1 F2-08-B25 (Hydro line) |

| Level Gauge | LG-03 (Hydro line) |

| Working pressure | 90 Kg/Cm2 |

6) Run out Table

Roller type Run out Table

| Electricals and Integration | ||

|---|---|---|

| PLC & CONTROL PANELS | ||

| destined for Electrical controlling of line equipment | ||

| Fabricated sheet metal enclosure | ||

| Easy accessibly mounting of components | ||

| PLC control mechanism system for high accuracy in length control | ||

| Front panel with operator interface, push button panel, operating & indicators | ||

| For ease of operation operator pendent can be at difference desired place on line | ||

| Mains with 3 phase 4 wire necessary protections shall be arranged by us near main panel console. | ||

| * HMI 7” X 7” Touch Color screen | 01 | |

| * Variable frequency Drive ( VFD) Delta Make | 01 | |

| PLC Delta Make | 01 | |

| Encoder | 01 | |

| Contactor, relay, SMPS | 01 | |

| MM & Feet in length/ 5 length & Piece | ||

| Auto Single Piece System | ||

| Auto Breaking System | ||

| Power Cut Start to same length | ||

| Auto machine length counting |

Features

Shaft with double bearings for high strength.

Back cutter for change coil color.

Lamination unit with synthetic rubber.

Control panel with new design.

Delta make drive with PLC.

Yuken make hydraulic valve.

ABB make motor for long life.

350×150 heavy I-beam with heavy 12mm thick fabricated body.

different sizes for easy and fast production.

Easy to operate and fully automatic machine.

7” HMI (touch screen) with very good graphics quality.