Double Decker Machine With Tile Press

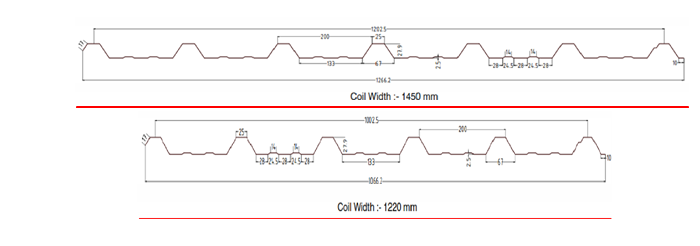

1220mm/1450mm Corrugation , Roofing & Squire Tile Press Profile Machine

Technical Information

- GENERAL SPECIFICATION FOR ROOFING LINE PRODUCE 1220mm-1450 mm Corrugation , Roofing & squire Tile press Profile

| Line offered is designed to process material as below | |

|---|---|

| ➢ Type of material to be Processed | PPGL / PPGI / NCGI |

| ➢ No. of Station | 24 |

| ➢ Max Width of Coil | 1450 mm |

| ➢ Min. Width of Coil | 500 mm |

| ➢ Max thickness of coil | 0.8 mm |

| ➢ Min. thickness of Coil | 0.2 mm |

| ➢ Variable Line Speed | 0 TO 25 mtr. / min |

| ➢ Automation level in performance | P.L.C CONTROLLED LENGTH |

| ➢ Accuracy Level | Length : +/- 2 M.M. BEND /TWIST : 1.5 MM/MTRDIMN : +/- 2 M.M |

Equipment List

- De Coiler 10 MT capacity – (Hydraulic)

- Roll Forming Machine – (24 stand ).

- Roll Tooling –

- Hydraulic profile cutting press.

- Hydraulic Power Pack.

- Run out Table.

- PLC type control panel.

- Film guard attachment & Back Side Cutter

9. Tile press 1220 & 1450 mm

Detail Line Specification

| 1) De Coiler -10 Ton Capacity | |

|---|---|

| ➢ All steel body construction | |

| ➢ Mandrel rotation | Automatic |

| ➢ Mandrel expansion by | Automatic |

| ➢ Loop System | Automatic |

| ➢ Breaking | Simple Brake |

| ➢ Max Width of Coil Can be Loaded | 1450 mm |

| ➢ Min width | 500 mm |

| ➢ Mandrel face length | 1400 mm |

| ➢ Drum nominal dia. | 500 |

| ➢ Drum expansion range | 470 to 550 mm |

| ➢ Max. weight of coil can be loaded | 10,000 kg |

| ➢ Motor | 5 Hp |

2) Roll Forming Machine

➢ Fabricated machined bed.

➢ Plate type work station option

➢ All roll shaft mounted on Ball Bearing

> shaft material EN-8 Roll EN 31

➢ Entry guides with vertical guide rolls & lateral movement manual screw type.

➢ Intermediate side guides with vertical guide rolls & all lateral movement manual screw type.

➢ Roll tooling material suitable for PPGI coil.

➢ Roll tooling manufacturing on C.N.C. machines.

➢ Drive Mechanism will be chain drive.

| Roll Forming Machine | |

|---|---|

| ➢ No. of workstation | 24 |

| ➢ Max width of coil | 1450 mm |

| ➢ Min. Width of coil | 500 mm |

| ➢ Max. Thickness of coil | 0.8 mm |

| ➢ Min. Thickness of coil | 0.2 mm |

| ➢ Centre distance of lower shaft to base plate | 150 mm |

| ➢ Horizontal distance between two stations | 450 mm |

| ➢ Max. Vertical Cent. Dist. Between lower to upper shaft | 300 mm |

| ➢ Motor And Gear Box ABB MAKE | 15HP |

3) Roll Tooling

Forming Rollers material suitable for PPGI material super polished for long life & production without marking on profile. Above Configuration Roller suitable for profile as per following.

4) Hyd. Profile Cutting Press:- Ignis Type Cylinder Type Hydraulic

Cutting when profile ready as per require length +/- 2 mm and very good line speed. Press is designed for without slug while cutting.

➢ Fabricated heavy duty base frame .

➢ High speed operation.

➢ Linear guide brass bush very useful when machine running high speed and constantly.

➢ Press is adjustable in 2 axis for align with profile output.

➢ More strength through Rack and pinion.

| 4)Hyd. Profile cutting press:- Ignis type Cylinder Type Hydraulic | |

|---|---|

| ➢ Working capacity | 20 Tons |

| ➢ Hydraulic Power Pack | 120 Liters |

| ➢ Pump | 01 |

| ➢ Filter | 01 |

| ➢ Solenoid valve | 02nos. |

5) Hydraulic Power Pack

➢ Tank Fabricated Capacity 120-Lts

➢ Motor 5 HP 3face 1440 rpm F class flange ABB

➢ Direction control valve:- NG-06-24v DC (Yuken)

➢ Pump :-1P series 27 LPM Dowty

➢ Section filter :- SC3 – 30 (Hydro line)

➢ Return line filter :-T1 F2-08-B25 (Hydro line)

➢ Level Gauge LG-03 (Hydro line)

> Working pressure :- 90 Kg/Cm2

6) Run out Table :-

➢Roller type Run out Table

7) Electrical and Integration

PLC & CONTROL PANELS

* destined for Electrical controlling of line equipment.

* Fabricated sheet metal enclosure.

* Easy accessibly mounting of components.

* PLC control mechanism system for high accuracy in length control.

*Front panel with operator interface, push button panel, operating &indicators.

*For ease of operation operator pendent can be at difference desired place on line.

*Mains with 3 phase 4 wire necessary protections shall be arranged by us near main panel console.

* HMI 4” X 6” Touch Colour screen- 01

* Variable frequency Drive ( VFD) Delta Make- 01

* PLC Delta Make- 01

* Encoder Delta Make- 01

* Contactor, relay, SMPS -01

* MM & Feet in length

* 5 length & Piece

* Auto Single Piece System

* Auto Breaking System

* Power Cut Start to same length

* Auto machine length counting

Features:-

➢ Shaft with double bearings for high strength.

➢ Back cutter for change coil colour.

➢ Lamination unit with synthetic rubber.

➢ Control panel with new design.

➢ Delta make drive with PLC.

➢ Yuken make hydraulic valve.

➢ ABB make motor for long life.

➢ 400×180 heavy I-beam with heavy 12mm thick fabricated body.

➢ 10 different sizes for easy and fast production.

➢ Easy to operate and fully automatic machine.

➢ 7” HMI (touch screen) with very good graphics quality.

> 20mm Plate Fabricated Body Stand