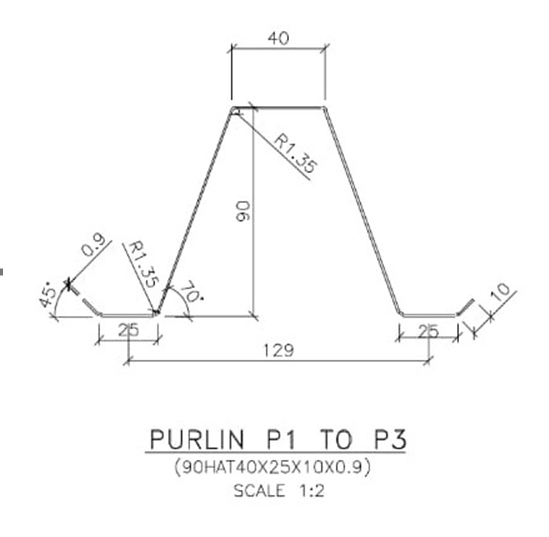

HAT Profile Roll Forming Machine

| Main roll forming machine | |

|---|---|

| Number of forming stands | 18stand |

| Outer diameter of shaft | 80mm |

| Height | 60 To 110mm |

| Main motor power | 10 HP (ABB) |

| Thickness of profile | 0.800 To 1.600mm |

| The forming speed | 8-10 M/min |

| Roller Material | EN-31 |

| Motor | ABB make |

| Voltage | 440V-50HZ – 3 Phase |

| Cutting system | hydraulic , automatic cutting |

| Weight of coil | 2000kg max |

| Length of the machine | 20-22 ft |

| Weight of machine Approx | 4 ton approx. |

The Equipment Includes:

De-Coiler (Hydraulic 2 ton )

Main roll forming machine 18 Station

Hydraulic cutting unit

Electrical control system

Hydraulic power pack

| Technical Specifications And Details | |

|---|---|

| De-Coiler | (Hydraulic) |

| Weight of the machine | 1200 kg |

| Capacity | 2000 kg max |

| Coil id | 510 mm |

| Max coil width can be loaded | 500 mm |

| Min coil width can be loaded | 50 mm |

| Main Roll Forming Machine | |

|---|---|

| Number of forming stands | 18stand |

| Outer diameter of shaft | 80 mm |

| Main motor power | 10HP |

| The forming speed | 8-10 meter/min |

| Roller material | EN-31 |

| Motor | ABB |

| Voltage | 440v-50hz-3 phase |

| Cutting system | hydraulic, automatic |

| Weight of coil | 2000 kg |

| Length of the machine | 20-22 ft |

| Weight of machine Approx | 4 ton approx |

| Hydraulic Power Pack | |

|---|---|

| Tank fabricated capacity | 80 ltr |

| Motor 2 HP ,3 phase, 1440 RPM, flange, ABB Direction control valve | NG-06-24v-DC |

| Pump | 1P series 27 LPM |

| Section filter | SC3-30 |

| Return line filter : Level Gauge LG-03 (Hydro line) | T1 F2-08-B25 (Hydro line) |

| Working pressure | 90 kg/Cm |

Electrical Control System.

Destined for electrical controlling of line equipment

Fabricated sheet metal enclosure

Easy accessibly mounting of components

PLC control mechanism system for high accuracy in length control.

Front panel with operator interface, push button panel, operating & indicators.

For ease of operation operator pendent can be at difference desired place on line.

Mains with 3 phase 4 wire necessary protections shall be arranged by us near main panel console.

HMI 7”x7” Touch colour screen Variable frequency Drive Encoder Contactor, relay, smps,

Auto single phase system auto machine length counting